Medical Heat Treating

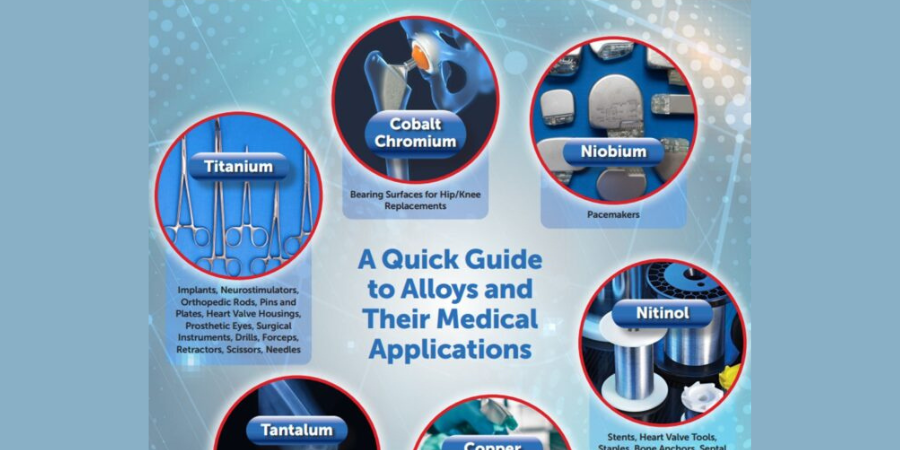

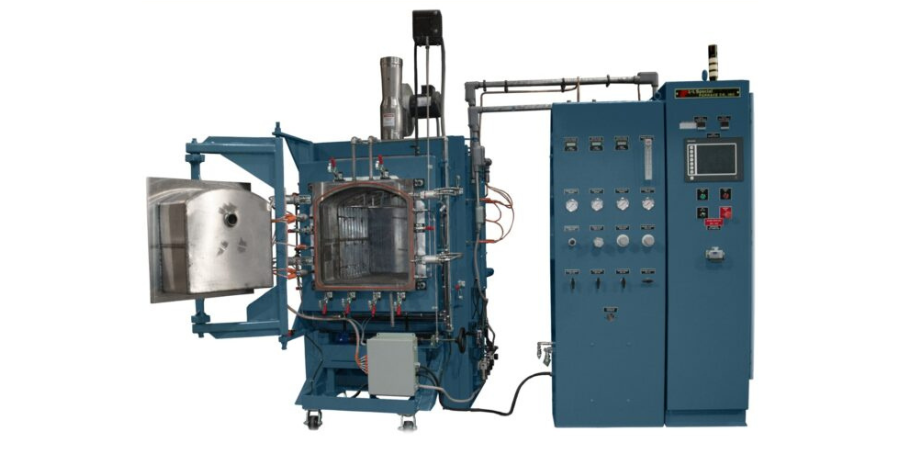

Medical heat treating includes products designed for both non-implantable and implantable medical devices. Non-implantable (e.g., surgical and dental instruments, dental impression trays, guide pins, hypodermic needles, storage cabinets, holloware, etc.) usually are manufactured from austenitic stainless steels that can be manipulated into complex shapes. Heat treating implantable medical devices (e.g., screws, joint replacements, bone plates, etc.) requires strict quality control to ensure no impurities are introduced into the human body. Common materials used in medical implantable devices are titanium or cobalt-chromium-molybdenum alloys. Medical industry heat treating is usually done in vacuum or argon gas atmosphere. Newer technologies in the medical industry include hot isostatic pressing (HIP) along with metal injection molding (MIM), and additive manufacturing (AM) both involving powder metallurgy techniques. Below is a collection of medical related news and technical articles.