MIHEU, a commercial heat treater for the steel processing industry, recently expanded its vacuum furnace line for processing large dies at its hardening plant with a single-chamber vacuum furnace.

The SECO/WARWICK furnace will allow MIHEU to increase processing capacity while maintaining precision, joining three other vacuum furnaces purchased from the supplier. The vacuum furnace with high pressure gas quenching includes large load capacity and workspace with an option to make adjustments for an oversized load.

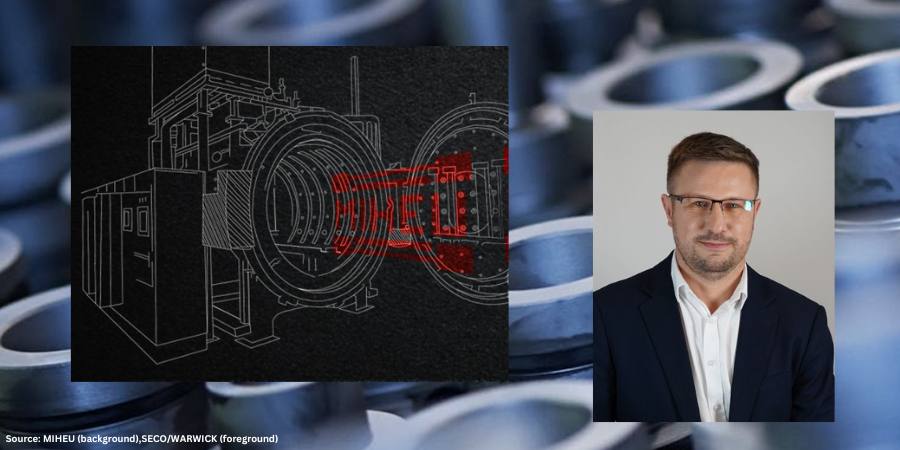

Sales Manager

SECO/WARWICK Group

Source: LinkedIn

“The Vector vacuum furnace will solve the challenge of hardening large dies, because it uses a large working space,” said Jędrzej Malinowski, sales manager of SECO/WARWICK. “The furnace is equipped with convection heating — a system which improves the heat transfer efficiency when heating at lower temperatures, as well as directional cooling, which allows for cooling problematic shape elements in various ways.”

“We wanted a solution which would shorten the heat treatment cycle time,” commented Aleš Prikeržnik, managing director at MIHEU Slovenia. “By expanding our machine park with a new vacuum furnace, we will significantly shorten the waiting times for customer orders. . . . We already have three such solutions and we are very pleased with their operation.”

MIHEU is a Slovenian commercial heat treating center with a range of additional services, including traditional hardening and tempering in oil in pit furnaces, carburizing, carbonitriding, nitrocarburizing, hardening in vacuum furnaces, and all types of nitriding, gas and plasma nitriding processes.

The press release is available in its original form here.