Sludge, scale, and dirt are all undesirables in quench oils that can cause detrimental effects during quenching. Bag filtration and centrifuge filtration are put to the test in this investigation. Compare the results before you make your next purchase.

This Technical Tuesday article, written by Greg Steiger, senior account manager, and Michelle Bennett, quality assurance specialist, at Idemitsu Lubricants America, was originally published in November 2023’s Vacuum Heat Treat magazine.

Introduction

The primary role of a quench oil is to dissipate the heat from a quenched load safely, quickly, and uniformly. Both sludge and heat scale have a higher heat transfer coefficient than quench oil and dissipate heat more than this quench medium. This can affect the performance of a quench oil.

To obtain the desired metallurgical results, the operation of a quench system must be both consistent and uniform. The presence of sludge from quench oil oxidation and scale within the quench oil, pump, and heat exchangers can lead to variability in key parameters such as grain size, hardness, case depth and surface finish. The best way to minimize the detrimental effects of sludge and scale is to remove these contaminants by filtration. This article will compare the two most popular types of commercial filtration available for oil quench systems: bag filters vs. centrifuge filtrations.

This article will compare the two most popular types of commercial filtration available for oil quench systems: bag filters vs. centrifuge filtrations.

Test Methods

To simulate a two-stage bag filter, the following lab procedure was followed.

A 300-mL sample of used quench oil was passed through a 75-micron filter paper. The filtrate from the 75-micron filter was then filtered through a 25-micron filter paper. To simulate the pressure typically found in an industrial bag filter, the filtration in both the 75-micron and 25-micron papers was aided by a vacuum pump that pulled used quench oil through the filter paper.

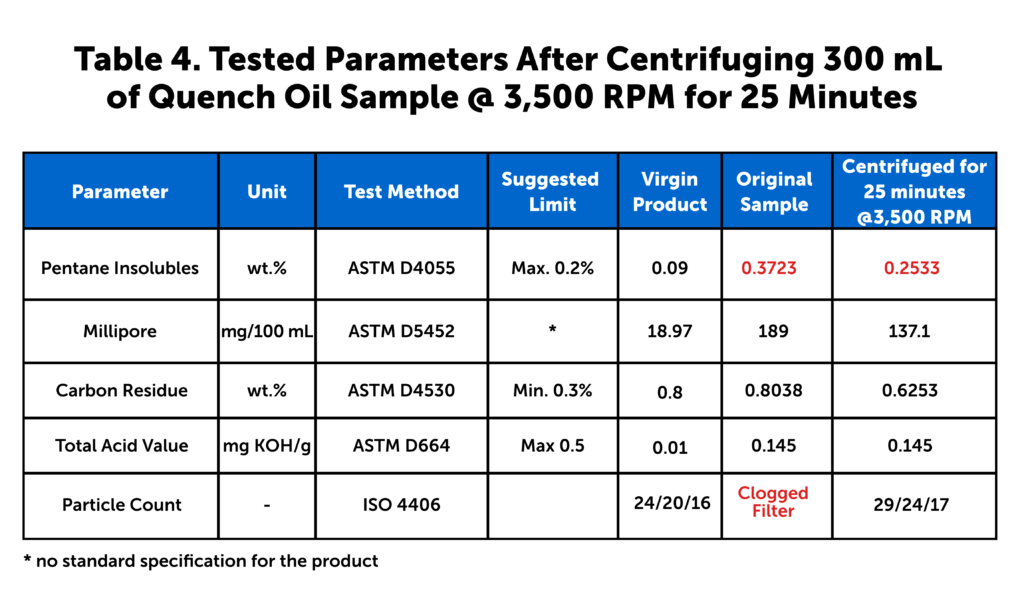

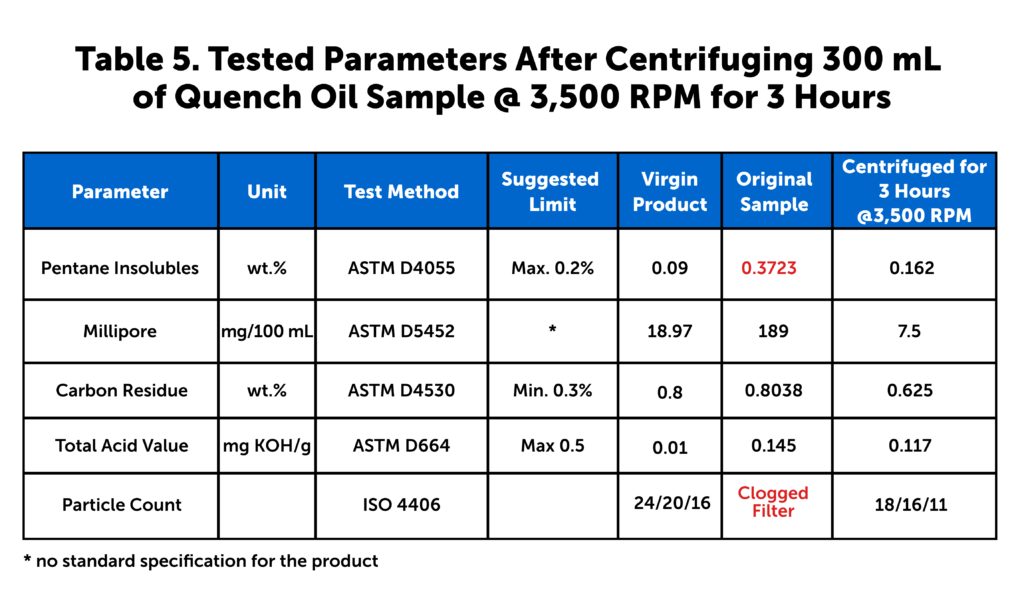

To simulate the effects of centrifugal separation, a benchtop centrifuge was used. A 300-mL sample of used quench oil was placed in a centrifuge tube and centrifuged for 25 minutes at a speed of 3,500 RPM. An additional 300-mL sample was placed in an identical centrifuge tube and centrifuged for 180 minutes at 3,500 RPM as well.

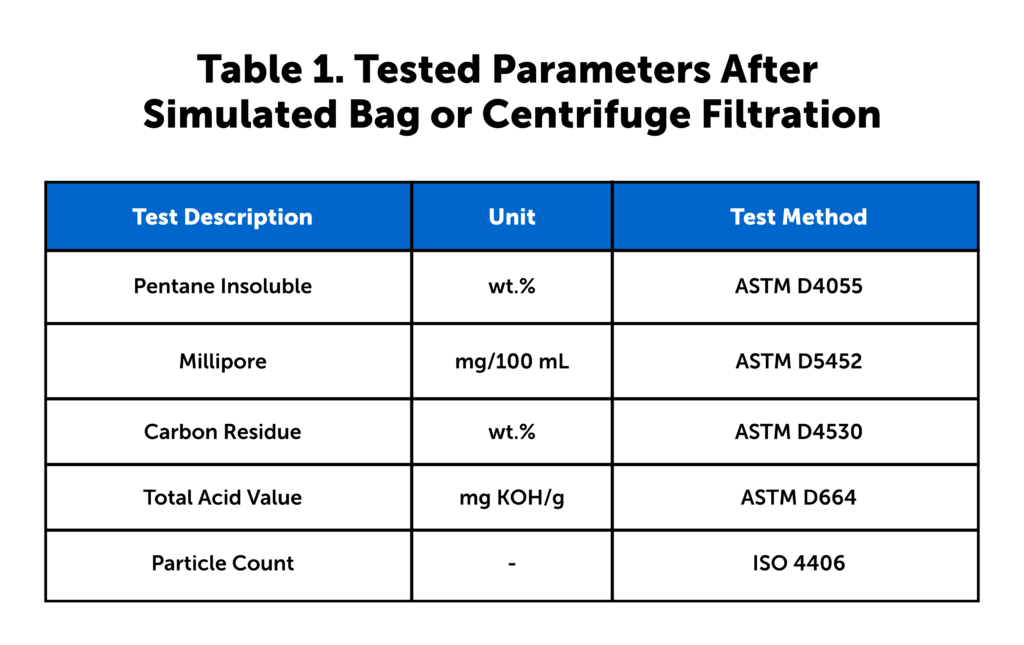

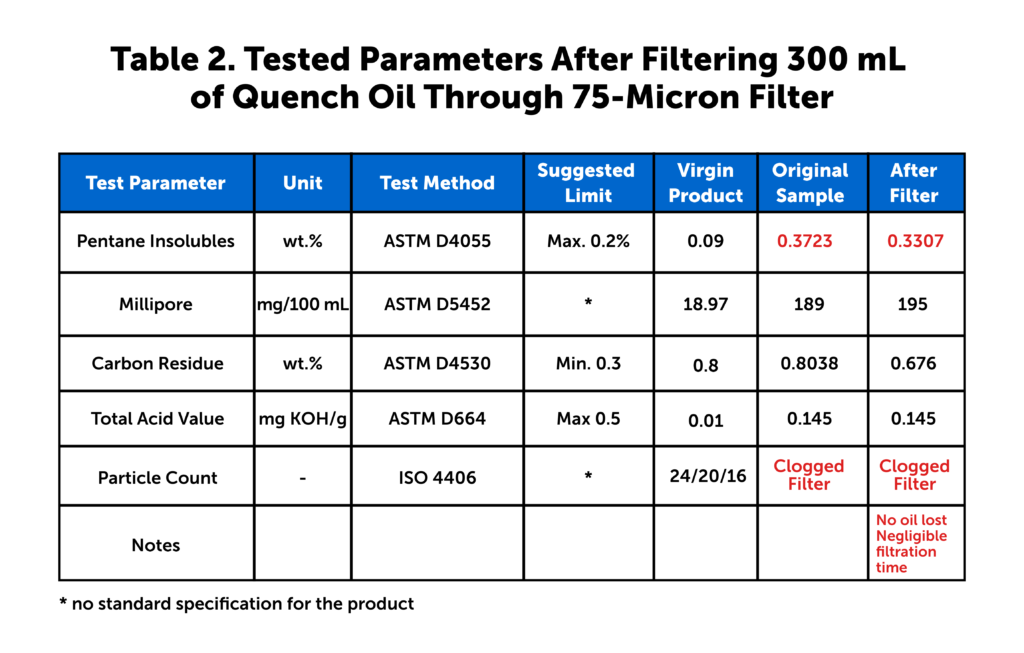

In addition to the lab testing of dirty quench oil samples, we monitored the particle count and pentane insolubles in samples from an in-use heat treating furnace. This study began with charging the furnace with clean quench oil that was filtered using a single stage 25-micron filter and collected after each filtration. At the conclusion of each timed centrifuge session, the filtrate and the centrifuged sample were tested across five tests, see Table 1.

Idemitsu Lubricants America)

Note on Table 1: Pentane insolubles measure sludge and scale present in the quench oil after the filtration through the barrier filter or after the centrifuge. Millipore testing is a measure of the overall cleanliness of the quench oil after either filtration or centrifuging. Carbon residue testing measures the Conradson carbon in the filtered or centrifuged quench oil and is designed to determine if any of the quench speed improver additive in the quench oil has been removed via filtration or centrifuging. By measuring the total acid number (TAN) of the quench oil, it is possible to determine if the quench oil is becoming oxidized and beginning to create unwanted sludge. The ISO Particle Count tests for solids contamination, providing a quantitative value for the number of particles that are larger than 4 μm, 6 μm, and 14 μm.

Filtration Results

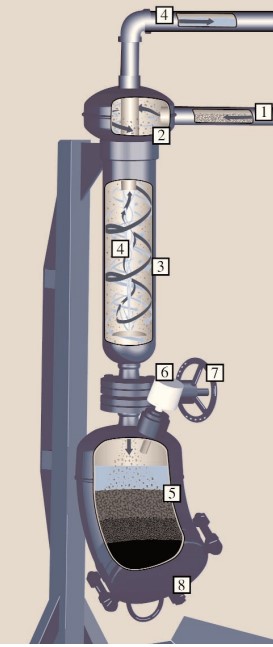

Because industrial quench oil filters are under a slight pressure, it would be very difficult to replicate this in a laboratory setting. To simulate the slight pressure found in industrial oil filters, we used a Buchner funnel connected to a vacuum pump to simulate the industrial pressure vessel. A similar setup is depicted in Figure 1.

The results post-filtration are depicted in Table 2 and Table 3.

(Source: Idemitsu Lubricants America)

(Source: Idemitsu Lubricants America)

Another popular method of filtration in a heat treating facility is through a centrifuge. While it is impractical to use a full-size industrial centrifuge in a lab, the same results can be achieved through the use of a smaller sample size and a benchtop centrifuge. A benchtop centrifuge similar to the one seen in Figure 2 was used to produce the results in Tables 4 and 5 (below).

Understanding the Test Methods: Bag/Barrier Filtration

Bag (or barrier) filtration is the most common type of filtration used in quench oil filtration. For the heat treater, there are many different size filters available, as well as different configurations varying in the number of canisters and filters. The filter creates a barrier that particles greater than the pore size in the barrier cannot pass. The primary reasons for its popularity are economics, simple operation, and design. A typical polyethylene bag filter and filter cannister can be seen in Figure 3.

The most common filter sizes are 50-micron and 25-microns. Both 5-micron and 25-micron filters were used in this investigation because the test sample contained a high level of pentane insoluble. Additionally, since it is commonly thought that using a 50-micron filter will cause blinding and clogging, we chose a 75-micorn filter and a subsequent filtration step of using a 25-micron filter to simulate a common two-stage quench oil filter.

Understanding the Test Methods: Centrifuge Filtration

Using a centrifuge to filter out sludge and scale is also commonly used in many heat treating operations. The difference between centrifugal filtration and barrier filtration is centrifugal filtration relies on gravity, friction, and centrifugal force to separate the particles from a quench oil instead of a physical barrier (Figure 4).

In the horizontal centrifugal filtration diagram, the dirty oil enters the tangential opening (section #1) and is forced into a spinning motion. A centrifugal force (occurring in section #2) is based on the spinning pentane insolubles, scale, and any other solids contained in the dirty oil.

In section #3, the friction created by the flow of the solids, scale, and other undesirables encountering the steel body of the centrifugal separator creates a low viscosity shear layer. In section 4, the clean liquid travels through a vortex and leaves through a side discharge. The slowing velocity of the undesirables allows gravity to pull them into the debris collection area in section #5. The now cleaned oil regains its velocity and continues through the vortex created by the centrifugal forces acting on the solids to a center discharge and back to the quench tank. As the debris fills section 6, a light will illuminate, indicating the receptacle is full and needs to be emptied.

Once the undesirables fill the debris collection area, an indicator light signals the receptacle is full and a gate knife control valve (section #7), is manually closed so the debris collector can be opened via the closure (section #8).

Discussion

As seen in Tables 2 and 3, filtration does improve the overall cleanliness of the dirty quench oil. The weight percent of the pentane insolubles showed a significant improvement when filtered through the 25-micron fi lter. However, the level of pentane insolubles was still outside of the suggested limits for the quench oil.

This was not seen when the quench oil was filtered through a 75-micron filter. The 75-micron filter had little or no effect on the Millipore results. The Millipore results increased when filtered through a 75-micron filter. This leads us to believe some of the particles within the dirty oil were forced through the 75-micron filter and not through the 25-micron filter, as the 25-micron filter showed an improvement in Millipore results.

An ISO particle count was not possible on the original used samples or the filtered samples because the filter clogged on all three test samples.

The largest difference in results lies in the carbon residue testing. The level of carbon residue is essentially the same after both the 75-micron and 25-micron filter samples. Both of the carbon residue levels are within the normal suggested limits. However, the high level of sludge in the original dirty sample is likely removing some of the quench speed improver from the quench oil. The removal of the quench speed improver changes the performance of the quench oil over time.

In examining the results of the centrifuge testing in Tables 4 and 5, it is clear centrifuging for 25 minutes has better effect on the cleanliness of the oil sample than filtering through a 25-micron filter. The level of pentane insolubles after centrifuging for 25 minutes at 3,500 RPM is still outside of the suggested limit. However, running the centrifuge for three hours under the same conditions not only brings the pentane insolubles within the suggested limits, the Millipore and particle counts also see an improvement over the virgin oil sample results. The carbon residue

levels behave much the same as they do in the filtration tests.

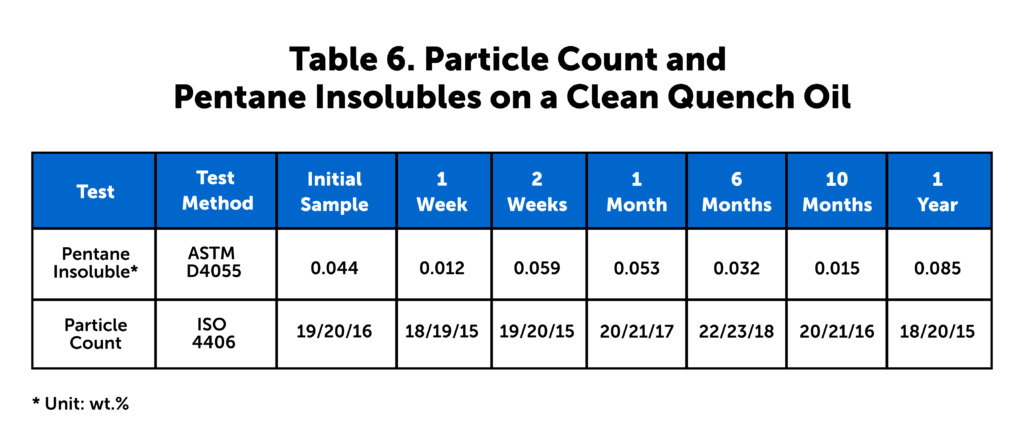

What is significant is the year-long study we conducted using actual customer data. In this study, a furnace was dumped, cleaned, and then filled with clean virgin oil. The authors then tested the ISO particle counts and pentane insolubles for one year after the furnace was charged with clean oil. These results are seen in Table 6. These data show essentially no change in the particle counts and a slight improvement in the level of pentane insolubles over the one-year period.

Conclusion

From the testing conducted, it is clear the filtration through a 75-micron filter has little to no effect upon the tested parameters and the performance of the quench oil. The high levels of pentane insolubles will likely clog heat exchangers, pumps, and valves within the quench system. The dirty oil will also likely cause metallurgical issues such as isolated soft spots due to the slower heat transfer of the dirty oil. The results of filtering a dirty oil through a 25-micron filter show some improvement in the pentane insoluble levels. However, the result is still outside of the recommended limits for the oil. Additionally, the ISO particle counts were not able to be tested due to the overall dirty condition of the filtered sample.

In contrast to the bag filter samples, the centrifuge samples showed a marked improvement over the dirty sample. While the pentane insoluble level was slightly out of the recommended limit for the 25-minute centrifuge sample, all results were within the recommended specifications for the three-hour centrifuge sample. In some cases, such as the particle count, the centrifuge sample had better results than the virgin sample.

While the centrifuge and filter results both show how hard it is to effectively clean a dirty quench oil, the results from the year-long study show very little difference in particle counts and a slight decrease in pentane insolubles, which can be explained through the normal addition of virgin make up oil to the quench system.

It is clear both centrifuge separation and bag filtration can improve the overall condition of a dirty quench oil. However, if your level of dirt, sludge, and scale reaches near the levels of the tested sample, a centrifuge is better at removing these than filtration. Overall, the data show the most important and efficient method is to begin filtering a clean quench oil as soon as the quench tank is charged.

About The Authors

Greg Steiger is the senior account manager at Idemitsu Lubricants America. Previous to this position, Steiger served in a variety of technical service, research and development, and sales and marketing roles for Chemtool Incorporated, Witco Chemical Company, Inc., D.A. Stuart Company, and Safety-Kleen, Inc. He obtained a BS in Chemistry from the University of Illinois at Chicago and recently earned a master’s degree in Materials Engineering at Auburn University. He is also a member of ASM International.

Michelle Bennett is the quality assurance specialist at Idemitsu Lubricants America, supervising the company’s I-LAS used oil analysis program. Over the past 12 years, she has worked in the quality control lab and the research and development department. Her bachelor’s degree is in Chemistry from Indiana University. Michelle is a recipient of Heat Treat Today’s 40 Under 40 Class of 2023 award.

For more information:

Contact Greg at gsteiger.9910@idemitsu.com

Contact Michelle at mbennett.8224@idemitsu.com.