Source: L&L Special Furnace Company

A leading Midwest manufacturer of custom firearms and rifles will use a medium-sized floor-standing box furnace for annealing gun barrels for rifles.

A leading Midwest manufacturer of custom firearms and rifles will use a medium-sized floor-standing box furnace for annealing gun barrels for rifles.

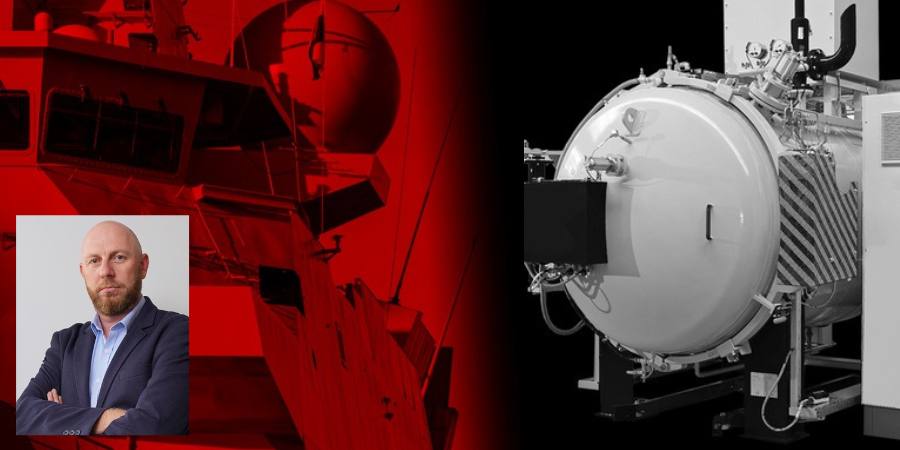

This is the second furnace from L&L Special Furnace Company that the manufacturer has acquired. This model is the L&L Model XLE 3636, which has a work zone of 34” wide by 30” high by 32” deep. It is designed for use with inert blanketing gas for atmosphere control to minimize surface de-carb.

Other features include a programmable flow panel with regulator and two flow meters for high and nominal flow rates along with a visual flow indicator light are included. There is a high-temperature air-cooled fan with packing gland to maintain the case seal integrity. A cast alloy hearth provides a good flat work platform for the fixturing of parts.

Honeywell controls and a Yokogawa recorder enable temperature control and chart representation of the furnace cycle. The power control is a series of solid-state relays and the furnace is constructed in accordance with NFPA86 compliance for safety.