Furniss & White has partnered with a stainless steel technology company to produce its castings at its heat treatment facility using a new series of high-performance alloys. The foundry, which specializes in high-integrity stainless steel castings, fabrications, and precision machining, has signed a long-term agreement to manufacture its cast products using the high-performance alloys.

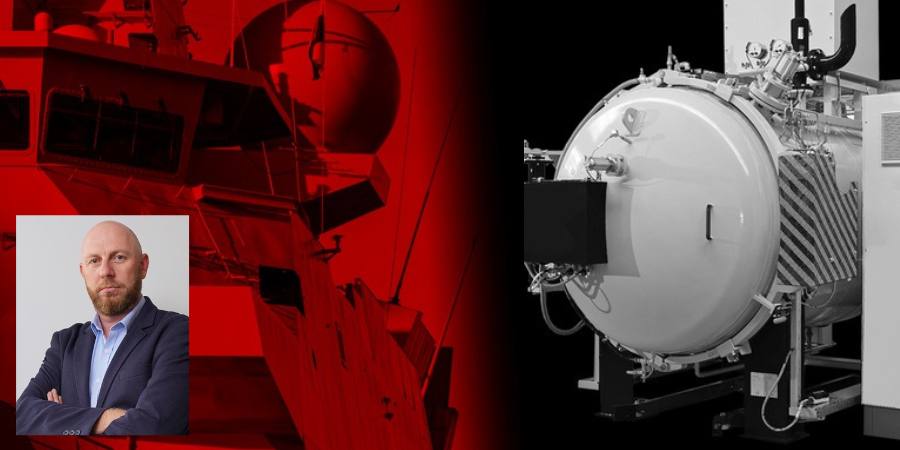

The castings are solution heat treated at approximately 1100°C (2012°F) and above and then water quenched by the company’s lift-off cover-type furnace with a load capacity of 5.3 tons (11,684.5 lbs). The N’GENIUS SeriesTM was developed by N’GENIUS Materials Technology and represents the total reinvention of conventional austenitic stainless steels, commonly known as the 300 Series.

Furniss & White will continue to produce its castings now using high-performance alloys under the N’GENIUS Series license for engineering products made using these advanced materials to its clients, serving the pump, valve, filter and engineering industries with castings from approximately 0.5kg to 2,600kg finished weight in a range of materials including carbon and low alloy steels, stainless steels, and nickel alloys. The firm manufactures an extensive selection of cast products for wide application in sectors including oil and gas, chemical, petrochemical, mining, marine, defense, and power generation.

CEO of N’GENIUS Materials Technology

Source: LinkedIn

“For more than 44 years we have built a strong reputation as a high-quality British manufacturer of high integrity castings made in our modern foundry in the UK,” said Sam Scholes, managing director at Furniss & White. “Now, as an approved licensed N’GENIUS manufacturer, we are writing an exciting new chapter in our history and to be the first foundry in the world to have this capability makes us extremely proud. We expect these game-changing N’GENIUS materials will be extremely popular with our existing customers and help open up new opportunities in other markets including the U.S. and Canada and in clean energy industries such as hydrogen.”

“Furniss & White is a company that shares our own passion and drive for innovation, and we are absolutely delighted to be collaborating with them on what is destined to be an industry changing technology,” said Dr. Ces Roscoe, CEO of N’GENIUS Materials Technology and inventor of the N’GENIUS Series. “With a long history of steelmaking, Sheffield is widely regarded as the birthplace of stainless steel and it seems befitting that it will essentially be ‘reborn’ in the same city more than a century later.”

Furniss & White has successfully completed a range of Manufacturing Procedure Qualification Tests at its facilities in various grades from the N’GENIUS Series.

Main image: Furniss & White casting an N’GENIUS grade alloy.

The press release is available in its original form here.