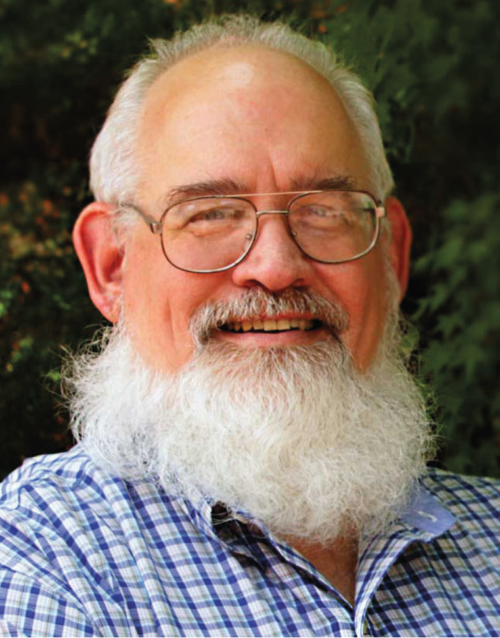

The search for sustainable solutions in the heat treat industry is at the forefront of research for industry experts. Michael Stowe, PR, senior energy engineer at Advanced Energy, one such expert, offers some fuel for thought on the subject of how heat treaters can reduce their carbon emissions.

This Sustainability Insights article was first published in Heat Treat Today’s December 2023 Heat Treat Medical and Energy print magazine.

PE, Senior Energy Engineer

Advanced Energy

The question in the article title is becoming increasingly popular with industrial organizations. Understanding the carbon content of products is becoming more of a “have to” item, especially for organizations that are in the supply chain for industrial assembly plants such as in the automotive industry. Many heat treaters are key steps in the supply chain process, and their carbon footprints will be of more interest to upstream users of heat treated parts in the future. I know I am overstating the obvious here, but I am going to do it anyway for emphasis:

- Heat treating requires HEAT.

- HEAT requires ENERGY consumption.

- ENERGY consumption creates a carbon footprint:

a. Fossil fuels heating — direct carbon emissions (Scope 1)

b. Electric heating — indirect carbon emissions (Scope 2)

Therefore, by definition and by process, if you are heat treating, then you are producing carbon emissions. Again, the question is, “How can we work to get the carbon out of heating?” Let us explore this.

Once more, heat treating requires energy input. The energy sources for heat treating most frequently include the combustion of carbon-based fossil fuels such as natural gas (methane), propane, fuel oil, diesel, or coal. Also, most combustion processes have a component of electricity to operate combustion air supply blowers, exhaust blowers, circulation fans, conveyors, and other items.

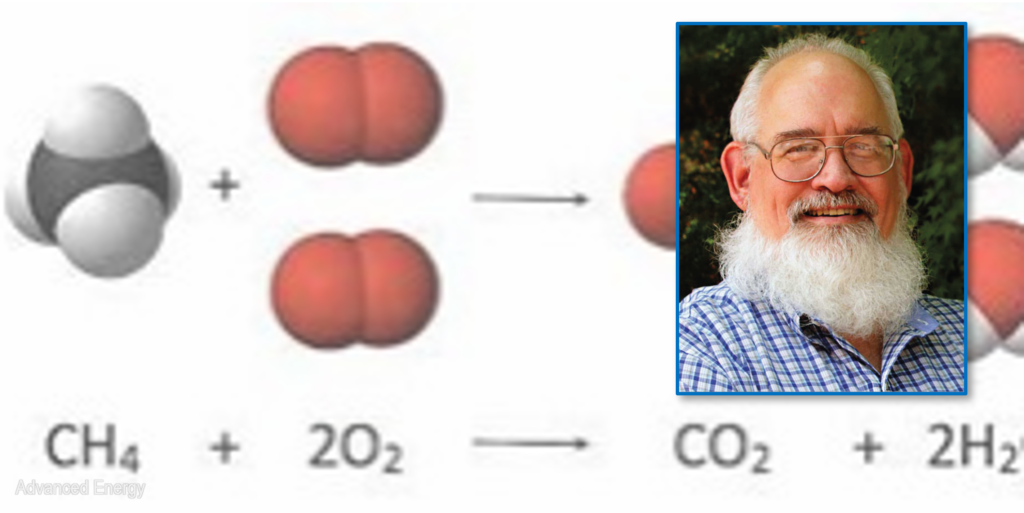

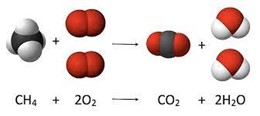

Figure 1 shows the chemical process for the combustion of methane (i.e., natural gas). Figure 1 demonstrates that during combustion, methane (CH4) combines with oxygen (O₂) to form carbon dioxide (CO₂) and water (H₂O). This same process is true for any carbon-based fuel. If you try to imagine all the combustion in progress across the globe at any given time, and knowing that all this combustion is releasing CO₂, then it is easy to see the problem and the need for CO₂ emission reductions.

In the most basic terms, if you have a combustion-based heat treating process on your site, then you are emitting CO₂. The electricity consumed to support the combustion processes also has a carbon component, and the consumption of this electricity contributes to a site’s carbon footprint.

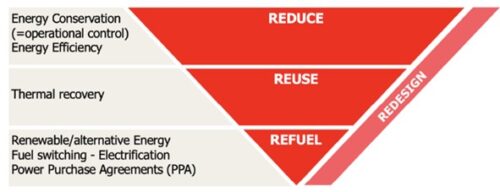

So, combustion and electricity consumption on your site contributes to your carbon footprint. Knowing this, organizations may want to consider the level of their carbon footprint and explore ways to reduce it. There are many methods and resources available to help organizations understand and work to improve their carbon footprint. For this article, we will focus on the 4 Rs of carbon footprint

reduction (see Figure 2).

We will discuss each of these approaches individually in priority order in the next installment of the Sustainability Insights.

For more information:

Connect with IHEA Sustainability & Decarbonization Initiatives www.ihea.org/page/Sustainability

Article provided by IHEA Sustainability