The race to space is in full swing with public and private sector companies staking their claim in this new frontier. And breakthroughs in technology and materials offer the potential to propel humanity to unprecedented distances. Success hinges not only on the ability to discover novel solutions but also on the capacity to prepare those solutions for efficient, large-scale production.

This Technical Tuesday article by Noel Brady of Paulo was originally published in Heat Treat Today’s March/April 2024 Aerospace print edition.

Space Today: Making Life on Earth Better, Safer, and More Connected

Source: Paulo

According to NASA, 95% of space missions in the next decade will stay in low Earth orbit (LEO) and geostationary orbit (GEO). Th at means the first wave of commercial activity in space will be largely focused on making life on Earth better.

Several worldwide broadband satellites are already in orbit, offering more consistent, reliable internet signals around the globe. Defense campaigns are using advanced satellite machine learning to improve asteroid and missile detection, along with revolutionary laser technology that has made intersatellite communication possible for the first time — and the travel of information faster. And to help make

life in space safe and successful, NASA is developing a scalable network of public GPS receivers for easy, short-range space navigation and tourism.

All this to say, parts are being developed for a wide range of applications, a huge portion of which are being additively manufactured.

Thermal Processing Standards Necessary for AM Adoption

However promising additive manufacturing is for space, the adoption of AM has still been limited due to the lack of standards for proprietary material and 3D printing applications. Many thermal processing experts are joining research institutions and OEMs in the drive to bring AM into mainstream manufacturing with new industry standards and production-ready solutions that help achieve ROI.

The R&D process for discovering these standards can be lengthy and expensive because it requires trial and error. A prototype or small run of parts must be manufactured, then heat treated, and tested for the desired properties. If a test part’s yield strength is not where it should be, for example, then the heat treating recipe is adjusted, perhaps by lowering the temperature and increasing the pressure, and can be tested again on a new batch of parts.

Coach vs. Custom Cycles

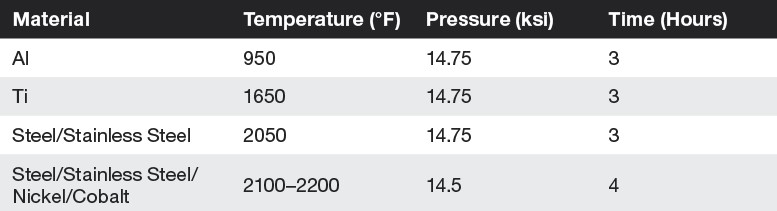

In heat treating, there are two different types of cycles, and it’s important to know the difference when you’re working with any commercial heat treater. Coach cycles tend to be more economical because these are shared cycles — existing recipes that are in high demand and run on a regular schedule — with the potential to have multiple clients’ parts in the furnace at once. For example, a heat treater may have a standard titanium coach cycle they run once a day. See Table A for several coach cycles run at Paulo.

Coach cycles use recipes that were designed for cast parts and have been around since before additive was a viable form of manufacturing. While it’s true that cast parts and AM parts have similarities, such as their high porosity, it doesn’t mean that the recipes are optimal for preparing today’s parts for heavy space applications. That’s where custom cycles come into play.

Custom cycles are ideal for new or proprietary materials that don’t yet have recipes defined or that are not commonly heat treated enough to run on a regular schedule. The distinction between the two is important because not all heat treaters are equipped to run both types. While you may be able to find a coach recipe that gets you close to where you need to be, it certainly may not be optimal, especially for parts that will have a heavy life of service.

Heat treaters with flexibility of custom and coach cycles, along with full-cycle data reporting, offer a high level of control that is vital for helping the industry progress and scale for production. This is also a big reason why some in-house heat treating operations may choose to outsource some of their work: first collaborating with experienced commercial heat treaters to prove the specification for a new part with custom cycles before scaling for production.

Common Cycle Adjustments for AM

There are five primary parameters that can be adjusted in the heat treating of AM parts to achieve the desired results: temperature, pressure, time, cooling rate, and heating rate. For AM parts, adjustments to the temperature and pressure are a go-to for achieving parts with higher yield strength. For example, running a cycle 50°F cooler, but at 5 ksi higher pressure may yield better results.

There may also be certain heating ramp rates and intermediate holds before parts get to the max temperature, to allow for consistent heating and enhance the material properties. The same goes for the cooling process: controlling the rate at which a part cools with specific holding times and intermediate quenches.

Hot Isostatic Pressing, Space, and Additive Manufacturing

Hot isostatic pressing (HIP) combines high temperature and pressure to improve a part’s mechanical properties and performance at extreme temperatures. The sealed HIP vessel provides uniform pressure to bring parts to 100% theoretical density with minimal distortion. The high level of control and uniformity has made HIP the gold standard for AM parts for space.

Similar to cast parts, 3D-printed materials tend to have porous microstructures that can compromise part performance. HIP is the only process that’s able to eliminate these pores without compromising the complex geometries and near-net dimensions that are achieved in the printing process.

Benefits of HIP for space parts include the following:

- Better fatigue resistance

- Greater resistance to impact, wear, and abrasion

- Improved ductility

For this process, Paulo’s Cleveland division is equipped with a Quintus QIH-122 HIP vessel, which is specially modified with additional thermocouples for more precise temperature control and greater data collection. A higher level of accuracy allows us to iterate with confidence and find an efficient path to production-ready development.

One primary benefit of the Quintus QIH-122 HIP is the ability to have faster cooling at a controlled rate, which allows you to heat treat and solution treat in one furnace. This cooling rate allows great efficiency that cannot be seen with other HIP vessels on the market.

It is critical that heat treaters adapt to meet the needs of this fast-evolving industry. Many commercial heat treaters do not yet have the level of data or dynamic cycle offerings necessary and will only run HIP coach cycles with set parameters. In other words, many are not equipped to economically iterate and adapt heat treating recipes for new parts. Without custom cycles, controlled cooling, and a higher level of data, it is impossible to push the boundaries of what’s possible.

Space Parts Requiring Thermal Processing

The future of space travel requires parts that can not only perform under high levels of mechanical pressure and extreme temperatures but are also durable enough for long-range and repeat missions. Heat treatment is a critical step in preparing rocket engine components, among others, for commission. Other space components commonly heat treat treated are:

- Volutes

- Turbine manifolds

- Bearing housings

- Fuel inlets

- Housings, support housings

- Bearing supports

- Turbo components

Since the inception of NASA’s Space Shuttle Program, Paulo has treated integral components for launch and propulsion, along with many parts currently in orbit on the International Space Station.

Materials Used in Space Parts

New materials and applications are being explored every day. Proprietary alloy blends bring unique properties and promising potential in the push for stronger, faster, longer-lasting parts. But with unique properties comes the need for unique heat treating processes. Several high-performance superalloys used for space include:

- Inconel 718, 625

- Titanium (Ti-6Al-4V)

- Hastelloy C22

- Haynes 214, 282

- GRCop Copper

Inconel 718, a championed space alloy, was originally used as a premier casting material before being adopted for AM. This nickel-based material features an extremely high tensile and yield strength that makes it ideal for components taking on a high mechanical load in extreme environments ranging from combustive to cryogenic — making this a natural material to adopt for space in the early days of 3D printing.

Because casting and 3D printing both result in similar porous microstructures, the heat treating process used for Inconel castings could also be adapted. Finding new opportunities within existing alloys like this is a highly efficient way to gain material advantage in today’s race to space.

To learn more about adapting alloys and heat treating processes for AM parts, download the full space guide.

About the Author

Noel joined Paulo in 2011 and spent several years as quality manager before stepping into his current role as a metallurgical engineer. Noel holds a bachelor’s degree in engineering and metallurgy materials science, and he is responsible for thermal process development and hot isostatic pressing process development.

For more information: Contact Noel Brady at nbrady@paulo.com or visit this link to download the full space guide from Paulo.