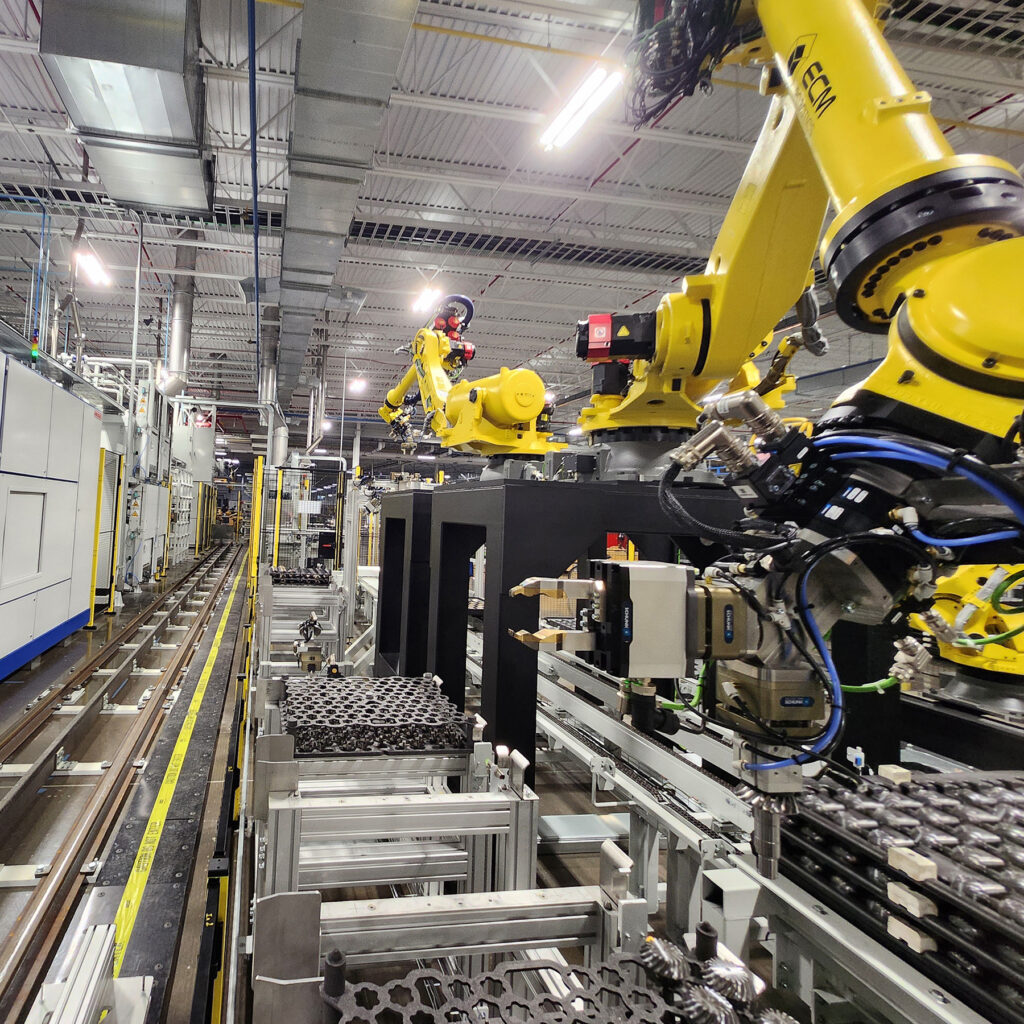

A modular NANO vacuum furnace system was commissioned for increasing in-house heat treat demands in drive technology. The furnace has reached its final acceptance.

SEW-EURODRIVE completed their fully automated in-house vacuum furnace system integrated with their patented MOVI-TRANS® inductive energy power transfer system (pictured parallel with ECM’s transfer system rails). SEW EURODRIVE partnered with ECM USA to commission the furnace which is completely integrated with advanced automation for their Lyman, South Carolina facility.

This 6 chamber, 20 bar quench NANO vacuum furnace system provides flexibility and integration utilizing the addition of 16 tempering positions, advanced solvent based washer (both oil and water based contaminants), and robotic workload assembly/disassembly. . . Specifically designed to run multiple materials (including carburized grades and tool steels) this system has modular flexibility to adapt to increased production demands for various load scenarios and processes.

Press release is available in its original form here.