![]() A company which has served construction, mining, and earth moving, but which is now involved in gas, power generation, military, aerospace, and more is Complete Heat Treating — this month’s MTI Member Profile company. They have many value-added operations under one roof combined with knowledgeable technical staff helping to select the optimum process to meet customer expectations.

A company which has served construction, mining, and earth moving, but which is now involved in gas, power generation, military, aerospace, and more is Complete Heat Treating — this month’s MTI Member Profile company. They have many value-added operations under one roof combined with knowledgeable technical staff helping to select the optimum process to meet customer expectations.

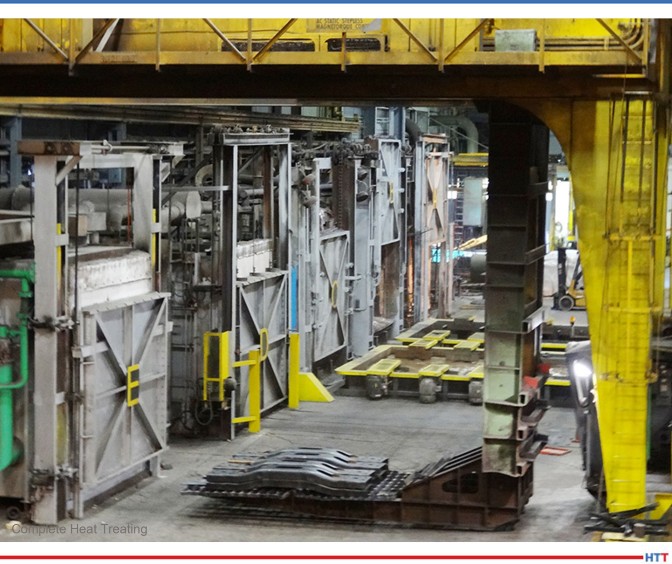

Complete Heat Treating was established in 2007 and has since acquired an additional two companies, increasing the company’s capabilities and markets. In 2011, they acquired Wisconsin Steel Industries, which was in operation since 1939. In 2018, they then acquired Commercial Heat Treat. After the acquisition in 2011, major rigging projects were undertaken to move furnaces, presses, and

other equipment to the present-day site in Milwaukee. One of the largest items moved was a large 53-foot car-bottom furnace.

A few of the company’s services include those in heat treating, blasting, coating,

straightening, and hardening. Heat treating capabilities encompass a wide variety of applications and part sizes. They offer stress relieving, annealing, quenching, tempering, and normalizing of parts up to 53’ long x 18’ wide x 15’ high and weighing up to 100,000 lbs. Open fire furnaces are available in multiple sizes and can reach up to 2200°F with heat outputs of 40,000,000 BTUs. In addition to having metallurgists on staff, other services offered are abrasive grit blasting, oil preserve coating, close tolerance straightening, and portable hardness testers.

Although all processes are important, control of the furnaces with properly calibrated pyrometry is critical to achieving quality specifications. The ability to successfully process the extreme size, shape, complexity, alloys, and quantity of parts is a unique feature of the company. They commonly heat treat large, heavy-section (10–20 ton) plates; 5,000+ tiny stampings weighing ounces; and finish machined precision parts with close tolerances. They can anneal, carburize, flame harden, straighten, blast—all to one part!

An interesting heat treat project is Complete’s involvement with large castings for the Space Launch System (SLS) for booster rockets. These were highly complex parts with a book of quality requirements.

They achieved the large heavy section mechanical property requirements and multiple hardness measurements to encompass the extremities of parts because of their procedural development that reviewed quenchant agitation direction and severity. Another interesting project involvement is the first

high-speed train in the U.S. It is a highly complex part consisting of castings, forgings, and plates with challenging quality requirements. The success of the lengthy procedural development made it memorable.

The company looks ahead to more memorable projects as new developments emerge, which include the commissioning of an integral-quench carburizing furnace and heat-treating aluminum components, and further expansion of flame hardening capability. Complete is best known for its diverse capabilities in both process and size of parts, but the quality of the 24-person workforce, their experience, technical competence, and honesty are the traits of which the company is proudest.