Heat Treat Radio #43: Andrew Bassett on AMS2750F (Part 3 of 3) — TUS Specifications

Heat Treat Radio host Doug Glenn continues his conversation with AMS2750F expert Andrew Bassett. This final discussion revolves around changes in temperature uniformity survey (TUS) specifications.

Heat Treat Radio host Doug Glenn continues his conversation with AMS2750F expert Andrew Bassett. This final discussion revolves around changes in temperature uniformity survey (TUS) specifications.

Below, you can either listen to the podcast by clicking on the audio play button, or you can read an edited version of the transcript.

Click the play button below to listen.

The following transcript has been edited for your reading enjoyment.

Doug Glen (DG): In this episode, Andrew Bassett and I have our third and final conversation about AMS2750F. Andrew Bassett is president of ATP and directly contributed his expertise to the latest revisions of AMS2750. If you haven’t heard the previous two episodes, you can find them by Binging or Googling Heat Treat Radio or by simply typing www.heattreattoday.com/radio into your browser.

In the first episode, you and I did some talking about just the AMS2750 generally; what it was, how it’s done, who was on the committee obviously, the fact that it’s not just a minor rewrite, but that it’s a major rewrite and then specifically in that first episode, we talked about thermocouples and calibration. Once we were done with that, we went into the second episode where we talked about system accuracy tests.

Andrew, again, tell our listeners who was involved on the committee. I know that from our perspective, the good folks over at GeoCorp had James LaFollete on the committee and I know Doug Shuler from Pyro Consulting was on there, but who else was on the committee that was responsible for putting this revision F together?

Andrew Bassett (AB): We had Marcel Cuperman from PRI (Performance Review Institute). He is one of the lead staff engineers for the NADCAP heat treat task group. We had Doug Matson from Boeing. Doug Matson, after the release of Rev F went into retirement. He has still been very active on any questions that have been arising with the Rev F. He’s retired, but he’s still in the loop with the specification. We had Brian Reynolds from Arconic. Again, we were looking for various people within the industry, so Brian Reynolds gave us a perspective from the raw material suppliers. We also had Cyril Vernault from Safran Aerospace. We wanted some European influence on the specification, and he is also the task group chairman for heat treat. We had a good, well rounded group of guys that were experts on this, to try to get this next revision put together.

DG: And yourself, of course. Let’s not forget that.

AB: I always like to say that I wrote the good stuff in there.

DG: Before we jump into TUS specifics and some of the major changes there, I want to hit just briefly on training. You and I were talking about this before we hit the record button. The fact of the matter is, there are several different training courses out there. Obviously, these three episodes ought to be helpful to you. A direct call to your cell or to Aerospace Testing and Pyrometry probably wouldn’t be a bad idea if somebody needed help with it. Does ATP also provide a training course?

AB: Yes, we do. We’ve always prided ourselves on providing AMS2750 training. Our training has always been customized to what our customers requirements would be, so every course is not the same. We like to take it to more than just AMS2750. You have to remember, there are other aerospace primes out there that have their own pyrometry requirements. For instance, GE Aviation has their own pyrometry requirements, P10TF3. Rolls Royce has their own pyrometry requirements. Or Pratt & Whitney might have some other things that need to be addressed. We actually sit down with our customers prior to any training and kind of take out the information that is needed, and then we perform the training onsite at the client’s facilities. So that if any other questions arise – “Hey, you’re talking about the SAT stuff” – then I can say, “Hey, let’s go for a field trip” and we can walk right out to the customer’s equipment and kind of demonstrate how to do, let’s say, a proper SAT or proper calibration. Again, we’ll cover various different specifications. For instance, one thing we like to do is find out what types of heat treating they’re doing. If they’re strictly a vacuum heat treating, I’m not going to talk about any of the aluminum requirements. There are some pyrometry requirements when it comes to aluminum, but we’ll talk about vacuum gauge calibrations, which is not covered under 2750, but is covered under AMS2769. Again, each one of our courses is customized to what our client’s needs are.

So, yes, they can feel free to reach out to us. There is myself and Collin Thomas who is an ex-NADCAP auditor for the two instructors for the course, and we’re more than willing to help out with that at any time.

DG: And just so everyone knows, at the end of this podcast, we will mention a couple of other companies and resources that you can go to for training on AMS2750F. I would like to mention, though, just a little self-serving note – and I did this with Google just a minute ago, though I don’t know that it will work on everybody’s location and what not… I Googled “AMS2750F” and Heat Treat Today came up as the second item with an article that we posted back on July 21st called AMS2750F expert analysis of which, Andrew, you were one of the contributors. We had five contributors, I believe, to that article, Doug Shuler being one of them, Peter Sherwin from Eurotherm being another, yourself being one and we had two others, Jim Oakes from SSI and Jason Schulze. I think you had to answer two or three questions and we compiled that. So that’s also a good resource to go to, if you have a moment to do so.

Let’s jump into temperature uniformity surveys (TUS). As we’ve done in the past, basically what we’re doing is asking you, “what were the major changes in this area?” So we’ve broken TUS into five basic questions. Let’s hit the first one now. Looking for the major changes in modifications and repairs section, tell us about that.

AB: In Rev E (the previous revision), there were two sections broken out called furnace modifications and furnace repairs. We put in there the caveat “but not limited to the following things.” If you replaced a hot zone in a vacuum furnace, or you changed thermocouple locations, these would trigger a major modification where you would have to do an initial uniformity survey. We basically took out the repairs function and just left in modification. If any kind of preventive maintenance, or some sort of maintenance function that is done, that would be considered a repair, it’s going to be up to the user’s quality organization to determine if any other testing is going to be required. For instance, if they replace a door seal around a door, quality is going to have to get involved and ask, “Do we need to do a uniformity survey?” What I always tell suppliers out there that are compliant with this is, get with your maintenance team, because the maintenance team typically will know whatever repair they did will have a major impact to maybe a uniformity survey. At that standpoint, repairs will have to be documented, as always, and then quality is going to have to sign off and ask, “Do we need another calibration, an SAT or a TUS?” We’ve put the onus back on the users now to determine if a test needs to be conducted. And then they’re going to have to defend that if they have an audit.

It was kind of silent in the previous revisions of the spec, but it was kind of mentioned that when you move a piece of thermal processing equipment from one corner of the building to the other corner of the building, that you were going to be required to do an initial uniformity survey. I brought up to the team, that these days, they actually make furnaces and ovens with wheels on them. This is for cellular manufacturing. If they have wheels on them to be moved to different locations, it again will have to be on the onus of the quality department to determine if another uniformity or initial survey needs to be done. Maybe they do a quick test on the furnace to make sure it’s within the same realm as the previous testing. We did say that initial TUS may be waived if the furnace is designed to be portable.

Some of the other major changes/modifications were people were always thinking if you changed your control thermocouple, when you replace it with a new one, that you have to do an initial survey. We always said no, you don’t have to do that as long as you put it back in the documented location. But I did see a problem with this when if they change the type of sensor, basically the thickness of the sensor. Maybe they went from a 3/16th sensor down to a 1/8th sensor. Well the 1/8th sensor is going to be more sensitive to temperature change and that could have a major impact on the uniformity. Or if they went from a hot junction that was not exposed to an exposed junction, this again increases the sensitivity. So we added in that as a major modification. If you do change that type of scenario on your thermocouples, then yes, you’d better do an initial uniformity survey.

And lastly, since we’re getting more and more advanced control systems, if you change the PLC logic, the PLCs that control a vacuum furnace or any other type of thermal processing equipment, then you better do an initial uniformity survey. So we kind of beefed up a little bit of the major modifications to address some of the newer technology that is out there.

DG: You said a lot of that was up to the quality department? Is that true, for example, when you went from a hot junction to not? Is that still up to the quality department?

AB: No. That’s now been changed under the major modifications that would trigger an initial uniformity survey. Changing from different types of sensors is not a repair, that is a modification.

DG: How about the way vacuum furnaces and the TUS’s need to be performed there? What were the major changes?

AB: There was really only one major change that we changed for when you conduct a survey on a vacuum furnace. Before, all you had to do was just do your typical uniformities within your temperature ranges for your qualified range of use and your vacuum pressure. If you had a diffusion pump, it had to get below one micron and then just do your survey. But then, I think it was Dr. Shuler, that brought up the idea that said, if people use a back fill gas or use partial pressure, maybe they just need to have one test under partial pressure.

At first, we got a lot of push-back from the suppliers on that saying this is going to cost them extra money and they would have to do an extra test. And we said, no, this is just part of your routine temperature uniformity survey schedule. We’re just saying, at least on an annual basis, you choose a single operating temperature within a defined partial pressure range that you use during production. We just want a survey done that way. You get to choose what gas you’re using, if you’re using argon or nitrogen. The thought process behind this was, if you had a needle valve that maybe was leaking and creating a cold spot in your furnace and you didn’t know about it, it’s more of a preventive thing to ask are those needle valves leaking and are you getting a cold spot in your furnace that you don’t know about. That’s all we’re asking, is just for one survey to be done in any one of your single set point temperatures with any partial pressure gas in the range that you define as your partial pressure. Once we explained it that way, we were able to get over that hump and move forward.

DG: It wasn’t as onerous as it initially sounded, apparently.

AB: Yes, I think the wording in the original draft sounded like it was going to be an extra survey, and I can understand the pushback from the suppliers. We explained that it was not an extra survey, it’s just one during your regular routine survey.

DG: Right. It replaces another one.

AB: Correct.

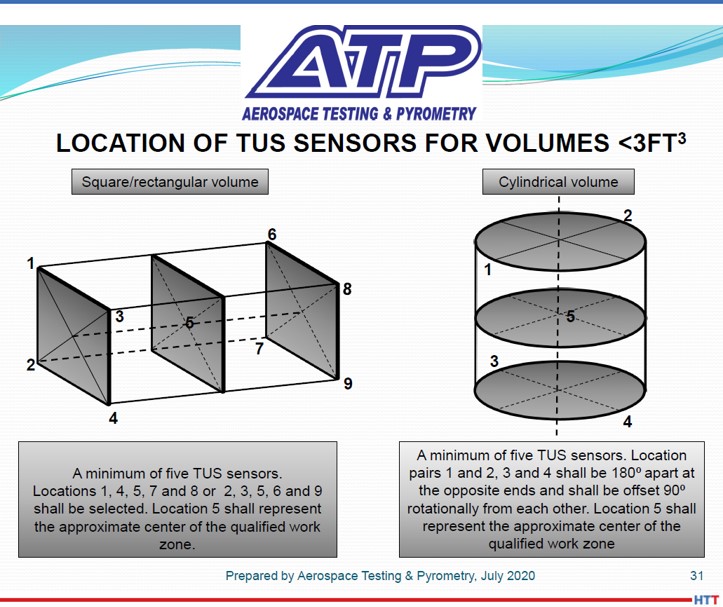

DG: Question 3. Location of the test thermocouples when you’re under 3 cubic feet.

AB: This was something that I always had an issue with in AMS2750, in the previous revision. How it was stated was that when you have a furnace less than 3 cubic feet, you can do a survey with five sensors. And it said that the five sensors shall be placed in the corners. Well, in a cylindrical furnace, you have eight corners, so what five corners do you choose? My understanding was that when NADAP PRI was teaching their pyrometry course, it was basically the central plane of the furnace. So you would have two thermocouples in the front that were in the center plane and then two in the back in the center plane and one in the center.

And I said, that doesn’t really work so well because you’re not really getting what’s on the top of the furnace or the bottom of the furnace. So, what we ended up doing was putting some new diagrams in the specification that showed that you’re going to go opposite corners. Let’s say you’re going to put one thermocouple in the top left corner in the front and then diagonally across from that will be one in the bottom right corner. Then in the back you would reverse those. So we are covering the top and bottom of the furnace. And the last thermocouple will be in the center. We spelled out a little bit better way of testing these smaller furnaces.

In a cylindrical furnace, it is stated that those thermocouples should be 180 degrees apart. Again, the NADCAP course would basically put five thermocouples in the center plane of a cylindrical furnace. And we said, no, we want two thermocouples on the top directly 180 degrees apart from each other and then two on the bottom, again, 180 degrees apart from each other, but they should be offset 90 degrees from the top one. You’re getting a better test of your full work zone dimension. I’ve always been doing these testings with these small furnaces in this method because that’s actually an older requirement from an old Boeing specification; the old BAC5621 actually spelled it out this way. We kind of adopted the old Boeing requirement of the smaller furnaces to show a better test for your small furnaces now.

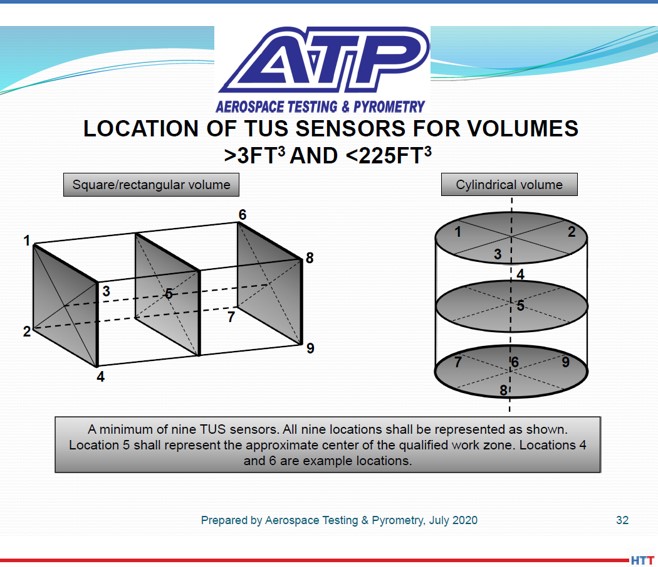

DG: Right. And let’s be clear, that is for a 3ft3 or smaller furnace. I assume, over 3ft3, you’ve still got nine thermocouples.

AB: Yes, greater than 3ft3 and less than 225ft3, you’ve still got the nine sensors. Once you get above 225 ft3, then the formula is in place in 2750F that spells out how many more thermocouples. I believe we don’t allow it to go past 40 thermocouples in some of those big monster furnaces.

DG: Let’s talk about aluminum for a little bit here. We’ve got radiation test surveys in aluminum furnaces, anything above 800°F; let’s talk about that.

AB: This is actually a surprise that this didn’t get some more pushback when we were putting the drafts out there. Originally, in previous revisions, it said all aluminum solution heat treating furnaces where the heat source is located in the wall, you had to do what’s called a radiation test survey. But we’ve changed the requirement to say all aluminum alloy thermal processing equipment used above 800, also with the heat source located in the furnace wall, ceiling or floor. This is a game changer because this will now put those aluminum vacuum braze furnaces into play. This was typically only a requirement for solution heat treating of aluminum alloys, but now it’s going to be for aluminum brazers. I’m very curious of how this is going to work. A radiation test survey is basically you have to have one 6061 aluminum panel that is 12 inches square with a test thermocouple peened into the middle of it and there is one panel for every 10 cubic feet of wall area. Basically, what we’re looking for is if there is any kind of direction radiation of heat to an aluminum panel as your panels are going to get extremely hot. What they’re looking for is eutectic melting. All aluminum heat furnaces, it’s required by AMS2770 which is the aluminum processing spec that says if you’re processing aluminum, there can’t be any direct radiation to the parts. But in a vacuum furnace, how is it heated? Direct radiation. I’m very curious as to how this is going to play out for those suppliers. Again, I was really surprised there wasn’t a whole lot of pushback from the aluminum vacuum braze facilities that have these types of furnaces that are now going to be required to do this test. It’s going to be interesting how that plays out once 2750 is in full force for everybody.

DG: Yes, and I guess we ought to say that it is not always radiation in a vacuum furnace. If you don’t have back fill gases, ok, it’s going to be all radiation. But if you’ve got some convective heat going on with back fill gases, that is possible. It doesn’t change the point that we’re making here. This is something for people to be aware of if you’re working with a vacuum furnace above 800°F, you’re doing any type of aluminum, then you’ve got a new requirement to do this radiation test.

AB: Yes. It’s the change of the words of ‘solution heat treating’ to ‘all aluminum alloy thermal processes.’

DG: Last question of the five. Documentation requirements. You mentioned there have been some changes. Tell us about those.

AB: We made a few changes to the documentation requirement. Basically from the standpoint of Rev E, we left everything from the original requirements in there, but people were unfamiliar with right after the section that talked about documentation. (The funny thing is we had to change it from reports to documentation. There was somebody that said we don’t want to call it a report because that quantitates that it has to be all in one package, we want to call it documentation. So we appeased that one.) Anyway, in Rev E, it was not part of the documentation records, but should be accessible on site, which were the control instrument tuning parameters, the PIDs or the proportional band reset rate, depending on the instrument manufactures, that those had to be documented for each thermal processing equipment. We thought this is being missed. There are a lot of places that I’ve been to where they don’t even know what the tuning parameters are. So we said from now on you’re going to have to document that in your TUS reports.

It also required to have a diagram of your TUS thermocouple location. That has always been a requirement, but we also now require you to show where the control thermocouple is placed and if you have any recording sensors. If you have type A instrument A or C instrumentation to have the high and low, those would have to be denoted on the diagram for part of the documentation package. We want to make sure that the supplier is aware that we don’t just need to see where your nine thermocouples are located, we also need to see where the control is and any applicable other sensors in the furnace that qualify for A, B or C.

We also want to find out, too, what type of atmosphere is being used in the furnace. Is it air? Is it a vacuum? Are you putting it under carburizing? You now have to list the atmosphere that was done during the testing as well. And then we’re also saying that the TUS test instrument that you’re using, you have to let us know what the correction factors are, even if you electronically apply them to the TUS instrument. You’re allowed to put in the correction factors prior to starting the TUS for your test instrument. A lot of people are saying it’s already been put into the recorder, I don’t need to document it. But we’re saying we still need to know what that correction factor is. So you need to document what those correction factors are.

There are two other things that are new to the documentation requirements. If you have types A or C instrumentation, again with the hot and cold thermocouples placed in there from the last uniformity survey, there shall be an analysis done to make sure that those locations have not changed. There are some requirements in Rev F that say if your uniformity survey is half your uniformity tolerance. In other words, if you’re testing for ∓10 and your final results come out less than ∓5, you can make an easy statement that my survey is within ∓5. No relocation of my hot and cold sensors are required. But you have to do an analysis of those two sensors for types A and C.

[blockquote author=”Andrew Bassett” style=”1″]We also want to find out, too, what type of atmosphere is being used in the furnace. Is it air? Is it a vacuum? Are you putting it under carburizing? You now have to list the atmosphere that was done during the testing as well.[/blockquote]

The other change deals with more of shaker type furnaces or continuous type furnaces, we call them continuous or semicontinuous furnaces. You have to list out what the traversing speeds are during your uniformity survey, maybe whatever your bump rate is for your shaker or the traverse rate. Then you’re going to have to recalculate what your work zone is. With a continuous type furnace, obviously your work zone will shrink the faster the belt goes through the furnace. There needs to be a recalculation of the work zone dimensions based on the survey based on what the belt speed should be.

And then lastly, like we’ve done with all the other documentation, if your service is being performed by a third party, the quality organization of the third party must also approve the reports as well.

Those are the major changes when it came to the documentation for temperature uniformity surveys.

DG: Basically, we’ve hit on three major areas. The first episode – thermocouples and calibration, the second episode – system accuracy tests, and this episode – temperature uniformity surveys. Are there any other odds and ends that you think our listeners should know about?

AB: Absolutely. There are a couple last minute things towards the end of this specification that already passed all the testing requirements.

The biggest pain when it came to Rev E is that we had the requirement for rounding, and that was to the ASTME29 method. That caused a lot of problems. I think we put a number on all the thermocouple suppliers because typically the thermocouple suppliers – when they’re doing their calibration of thermocouples – put everything into Excel. Well, Excel rounds .5 up, like we all learned in grade school. But, E29 doesn’t like that. They like to have if your next significant digit is odd, it rounds up; if it’s even, it stays the same. That put a little hamper on all of the thermocouple guys and we kind of didn’t think that one through.

So, now we’ve changed it in Rev F. The methods that you can use are ASTME29 using the absolute method, that still can stay the same, or you can use an equivalent international standard such as ISO 8001 rule B which is .5 round up, or you round to any commercial spreadsheet, in other words .5 round up. As long as you have documented procedures and you have to use it in a consistent manner. I should say we’ve relaxed the rules, so now you can choose what kind of rounding method you want to use.

We wanted to make sure that we spelled out, too, that all the tolerances in 2750F, if you look at Rev F compared to Rev E, all the tolerance requirements, we used to say plus or minus 10, now it says plus or minus 10.0. It’s an absolute. If you have a survey that you do that is 10.2 and you want to try to round that down, you can never round anything back into compliance. If something does fall out of tolerance by a 10th of a degree, or whatever, you cannot using the rounding function to bring it into compliance.

We addressed a hole that was left in Rev E on your test interval extensions. In previous revisions, we forgot about adding bimonthly and every four months, how many days you can go past an extension for a due date, so we finally addressed that in this revision. It used to be Table 10 and now it’s Table 25. The only thing that’s added onto this is if you do use an extension for any reason, there must be a written justification approved by the user’s quality organization. It can be as simple as: my test came due on Sunday, but I came in and did the test on Monday. You’re just going to have to write a note saying the due date was Sunday and you did it on Monday. You just have to write some justification of that.

Lastly, and I think this is a big thing, as well, is under the quality assurance provision. It is basically the section that says what happens if you have a pyrometry failure and so on. We didn’t change anything in there except two years after the release of Rev F, any third party pyrometry service organization must have a quality system approved to ISO 17025. Also, the scope of accreditation shall include laboratory standards and/or the field services applicable.

Third party service providers, two years after the release, will now have to be 17025 accredited. If they are, there is also no procedural oversight from the supplier. For example, since we’re 17025 accredited for our laboratory, we actually hold two different accreditations, one for our laboratory and one for our field service work for calibrations for uniformity surveys and system accuracy testing. Now, since we are third party accredited, our clients will not be required to have any oversight on us. Personally, I don’t think that’s the best option; I think the supplier should still be able to audit us and look at our procedures to make sure it’s compliant with the industry standards. But according to Rev F, there is no more oversight if we’re third party accredited.

I wasn’t a big fan of adding this in. Again, you would think people that are 17205 like ourselves would be happy to have this in there as it might weed out some other companies, but I’ve actually worked with some really good smaller shops – a two-man father and son that’s located in New York, and then a gentleman in California that is just a single guy, and these guys are very versed in the specification and do thing right. Unfortunately, now they’re going to have to be 17025 accredited. I talked to one of them and he said, “This may put me out of business. I don’t know if I can afford swinging this. I do a good job.” And I said, “I know, I’m trying to fight for you on this,” but it ended up going in. At least we put the caveat that they have two years to get it down, so it’s not something immediate.

DG: Yes, that is the danger when you start requiring certain accreditations, licenses or whatever. It’s typically the small guy that takes the beating. That’s too bad, but that’s the way it is… I shouldn’t be so flippant about that, should I? It is too bad!

AB: I really struggled. Originally, the first draft was going to be immediately, and I said, no, let’s put a moratorium on it for at least two years so people can queue up for that.

DG: I guess the moral of the story for the end user is within two years you need to be asking your third party survey companies/accreditation folks, whoever is coming in to do your pyrometry and whatnot, if they have this 17025.

Anything else? Any other odds and ends?

AB: The last thing I want to add about the 17025 is that this is only for third party suppliers. We’ve received questions like, We do our pyrometry internally, do I have to go get 17025? No, you don’t. It’s only for third party suppliers.

DG: Let’s wrap up with a couple of quick things here. Training. If there are listeners out there who want additional training. We talked at the beginning of this episode about what Aerospace Testing and Pyrometry, your company Andrew, what you guys can do. I’m going to list a couple of other places, I believe, have training, and then if you know of any others you’re comfortable mentioning, please feel free to do so.

I do know, you mentioned, PRI does some sort of training here on this. I believe, a good friend of Heat Treat Today, Jason Schulze up at Conrad Kacsik, have something, and I’m sure they can do custom. I don’t know if they have standard courses or not, but I’m sure they can do some custom stuff. And, I believe that Super Systems also has some sort of training on this. I believe GeoCorp does, or will. But those are the only sources I know. Correct me if I’m wrong on any of those and let me know if there are any other places that people could get training.

AB: I wasn’t familiar with Super Systems or GeoCorp, but everybody is getting onto this bandwagon. But the other course I would also know of is Doug Shuler’s Pyro Consulting as well. He does teach an advanced pyrometry course.

DG: First of all, Andrew, we really appreciate your time doing these three episodes. If people want to get a hold of you, what are you comfortable giving out? We don’t want to give out your cell phone, unless you’re comfortable with it, but certainly emails and things of that sort.

AB: They can give me a call on our office line which is 844-828-7225. If you press 1, that’s supposed to actually ring my cell phone, but sometimes it doesn’t and sometimes it does. You can try the office line or you can reach me through email which is abassett@atp-cal.com or you can hit us up on the website www.atp-cal.com and you can just hit one of the emails of support and let me know what you’re looking for from pyrometry training, or anything else for that matter, and I’ll be more than happy to reach out to you.

DG: If you’re interested in reaching out to Andrew, please try the above. Of course, I’m always willing to take emails and put you directly in touch with Andrew, if you’d like. You can do that by emailing doug@heattreattoday.com.

To find other Heat Treat Radio episodes, go to www.heattreattoday.com/radio and look in the list of Heat Treat Radio episodes listed.

Heat Treat Radio #43: Andrew Bassett on AMS2750F (Part 3 of 3) — TUS Specifications Read More »