Vacuum Heat Treatment’s Role in Additive Manufacturing (AM) 3D Printing

![]() Source: Global Heat Treatment Network

Source: Global Heat Treatment Network

“Vacuum heat treatment tasks for AM manufactured parts is the same process as traditional subtractive manufacturing and its purpose is to assure AM parts has the correct physical and metallurgical properties for specific applications. In some cases, when a bidder is involved, the purpose of the heat treatment process is to deciding and sinter parts. Most vacuum furnaces use up to 800°C degrees to relieve stress and a higher temperature of up to 1800°C for other processes.

Vacuum furnaces with high vacuum levels are preferred to heat treatment equipment to process AM parts. AM parts made from Titanium, Cobalt, Aluminum require vacuum levels of up to 10-6 mbar with 99.9995 Argon purity. Argon is the preferred gas because of its neutrality and that it has no adverse reaction with the above alloy components. Creating an Alfa surface layer on titanium parts is not desirable and should be avoided.

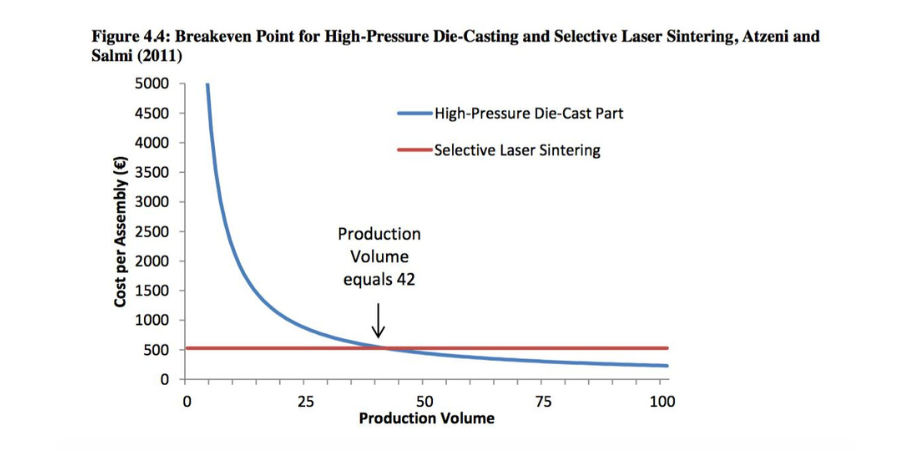

The small parts and small production volume influences vacuum furnaces of small to medium size. The next challenge for the heat treatment industry is to integrate heat treatment process into the AM equipment in one continuous process.”

Vacuum Heat Treatment’s Role in Additive Manufacturing (AM) 3D Printing Read More »