Precision Parts Manufacturer Acquires 2 Suppliers of Medical Device Components

A leading provider of precision parts recently announced the acquisition of two companies, both suppliers of tight tolerance, mission-critical components used in medical device, aerospace, and industrial applications.

MW Industries, headquartered in Rosemont, Illinois, which engineers springs, specialty fasteners, bellows, and other precision components has acquired both companies from SW Holdings, LLC: Marox, a manufacturer of machined orthopedic implants, and Sussex Wire, a manufacturer of mini and micro cold-formed parts.

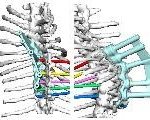

Located in Holyoke, Massachusetts, Marox produces precision machined orthopedic and spinal implants in a variety of complex geometries to leading orthopedic device firms. The company also manufactures components used on robotic surgery devices.

Sussex Wire, located in Easton, Pennsyvania, applies cold-forming and roll-forming manufacturing techniques to shape metal wire and special alloys into highly engineered, precision, micro-miniature components. These components play essential roles in medical device applications.

Both companies offer advanced engineering capabilities, material selection advice, and manufacturing know-how for creative solutions that shorten design cycle times and speed time to market.

“Adding Marox and Sussex Wire to our portfolio of medical solutions companies creates a set of technical capabilities and precision machining capacity that is unmatched in the industry,” explains John Bagnuolo, Chief Executive Officer of MW Industries. “Medical device OEMs and CMOs can rely on MW Industries for innovative, cost-effective solutions to their most complex design challenges.”

Precision Parts Manufacturer Acquires 2 Suppliers of Medical Device Components Read More »