Titanium + Gold = New Gold Standard for Artificial Joints

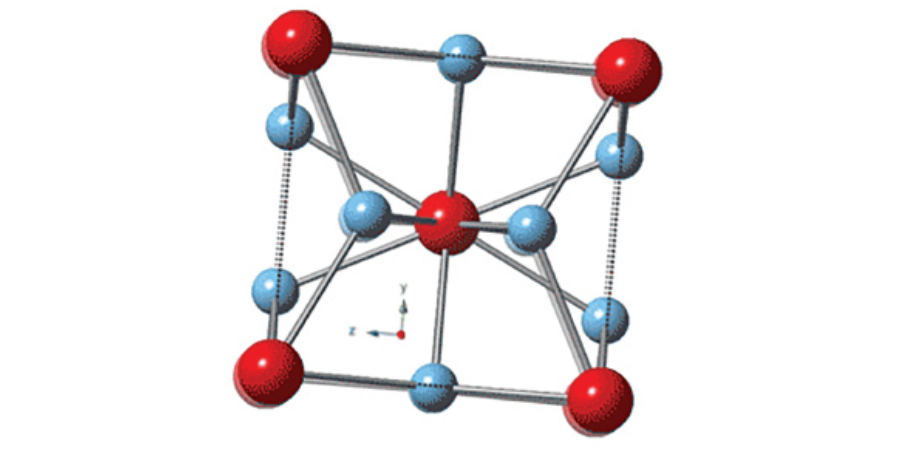

![]() Source: Rice University News and Media

Source: Rice University News and Media

“Titanium is the leading material for artificial knee and hip joints because it’s strong, wear-resistant, and nontoxic, but an unexpected discovery by Rice University physicists shows that the gold standard for artificial joints can be improved with the addition of some actual gold.”

Read More: Titanium + Gold = New Gold Standard for Artificial Joints by Jade Boyd and Co-Authors Pulickel Ajayan, Sruthi Radhakrishnan and Chandra Sekhar Tiwary, all of Rice; Tiglet Besara, Yan Xin, Ke Han and Theo Siegrist, all of Florida State; Fevzi Ozaydin and Hong Liang, both of Texas A&M; and Sendurai Mani of MD Anderson

Titanium + Gold = New Gold Standard for Artificial Joints Read More »