An international company producing, among other things, cutting tools, with a rich history and branches in 40 countries, ordered a vacuum furnace, their third order from them to date.

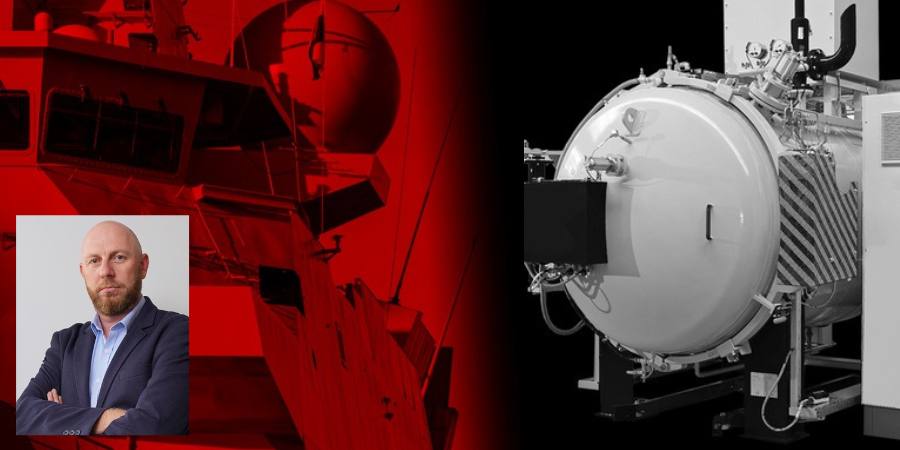

(source: SECO/WARWICK)

The horizontal, front-loading furnace, from SECO/WARWICK, will accommodate the customer’s needs with an all-metal hot zone for clean vacuum processing. As with the earlier furnaces, one of which was installed at a different facility, the new furnace includes a convection fan and a pressurized gas quench for quick cooling.

Maciej Korecki, VP, Vacuum Furnace Segment at SECO/WARWICK says, “Precision, high uniformity in heat treated parts, high consistency in workloads and high speeds in batch processing along with low energy and gas consumption makes our product most desirable solution on the market. Often our clients demand just one thing – for instance: high uniformity in heat treated parts which solves problems of distortions they experience using different technology. All the other features come as a surprise and an added value.”

According to Piotr Zawistowski, President, SECO/VACUUM, “This third repeat order is a testament to SVT’s on-time delivery and the performance of our . . . vacuum furnace to meet all promised parameters, including producing clean finished parts, all as promised.”