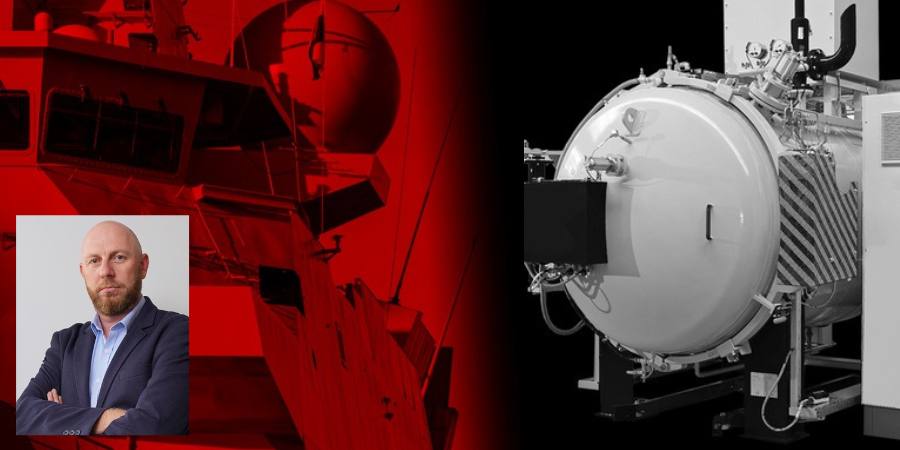

Director of sales

Solar Atmospheres of Western PA

Two large H13 extrusion dies for two separate companies were vacuum heat treated in a high pressure gas quench vacuum furnace that fully hardened the dies in successive cycles.

Solar Atmospheres, using a furnace from Solar Manufacturing, provided two Ohio companies as-quenched dies with hardness of HRC 50-52 using nitrogen as the quench gas. The hollow die was 30” outer diameter x 15” inner diameter x 103” long and weighed 16,000 pounds. The solid die, belonging to a different customer, was 34” outer diameter x 64” long and weighed 14,000 pounds. Post-quench each component was triple air tempered resulting in a final hardness of HRC 46-48.

The 10-bar 600 HP high pressure vacuum furnace permits the company to obtain the desired cooling rates, commented Mike Johnson, director of sales at Solar Atmospheres.