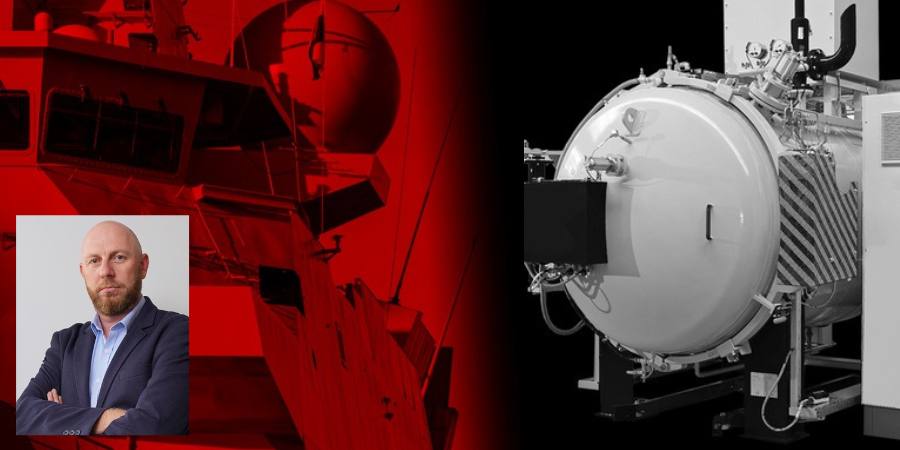

Mikros Technologies, located in New Hampshire, designs and produces liquid cooling systems and micro-machined nozzle plates for applications requiring micron-level dimensions and sub-micron accuracy. So when Mikros needed new multipurpose furnaces for vacuum brazing and diffusion bonding that could withstand continuous production and allow operators to seamlessly change recipes and easily pick up where the last person stopped, they turned to Ipsen USA. Mikros increased production capacity by purchasing two more TITAN® H2 2 bar vacuum furnaces. The first was installed in January 2019, the second in October 2019.

The furnaces met their needs by supporting a variety of heat-treating processes, providing tight temperature uniformity and delivering clean parts. With the high-efficiency design and fast door-to-door cycle times, the furnaces helped Mikros gain manufacturing volume to accommodate the company’s rapid growth.

As a leading provider of complex thermal management solutions for critical applications in power computing, laser optics, semiconductor testing, renewable energy generation, artificial intelligence, and electric vehicle systems, Mikros plays a critical role in allowing data centers and equipment used for transportation, aerospace, and defense to perform optimally and keeping high heat-generating components from overheating and failing prematurely. Some of the microchannel cold plates they manufacture are small and delicate, no larger than a penny. Others are large assemblies that occupy a full computing server rack. Specialized parts like these require careful planning when it comes to heat treatment.

In the last five years, Mikros doubled their workforce and expanded their manufacturing facilities. Mikros makes over 10,000 cold plates per year, and the addition of the furnaces has helped them quadruple their production capacity.