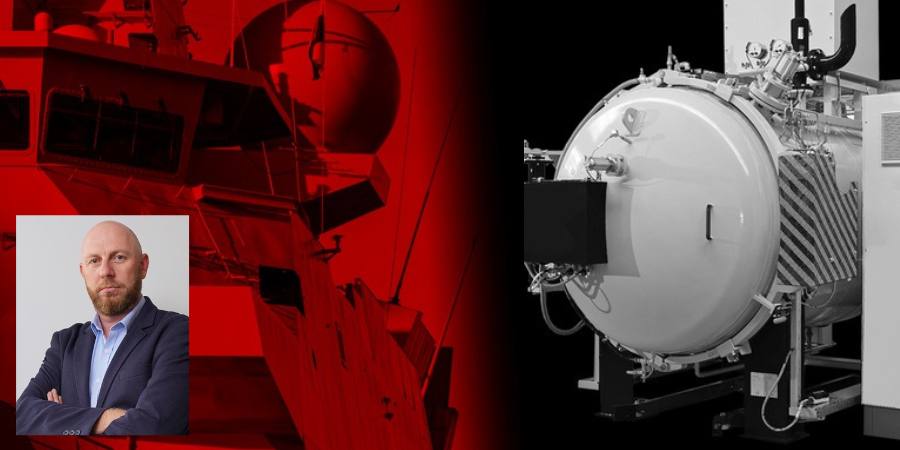

President

Solar Atmospheres of Western PA

Lake Park Tool and Machine, located in Youngstown Ohio, produced a massive H13 liner which Solar Atmospheres of Western PA (SAWPA)recently heat treated. The liner measured over 100” OAL and weighed a total of 16,000 pounds. The liner was turned on Lake Park’s new large capacity lathe with 34” max diameter and 200” max length.

This H13 liner was heat treated in, what SAWPA says is, "the fastest cooling large vacuum furnace in the industry." Solar Manufacturing, sister company to SAWPA, recently completed this 10 bar vacuum furnace several months ago. It is equipped with a hot zone measuring 48” wide x 108” OAL. Additionally, the furnace has a 600 HP blower motor for increased cooling power. The critical cooling rate, to obtain optimum properties for H13 hot worked tool steel, was achieved in the as-quenched hardness of HRC 54-55. The part was then double tempered to the customer’s specification of HRC 46 to 48.

"This large rapid cooling vacuum furnace provides us continued diversification to our vacuum heat treating repertoire and capabilities. We’re proud of this partnership with Lake Park Tool and Machine and to assist our customers in vacuum heat treating one of the largest air hardening dies that I have personally heat treated over my 40 year career,” stated Bob Hill, president of Solar Atmospheres.