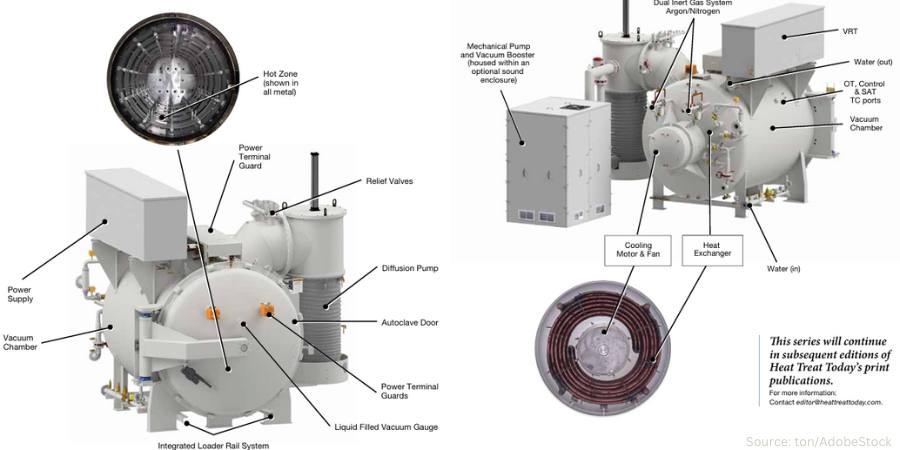

When you are a new heat treater, there are really only three things you want to know to get your bearings: What is it? How does it work? Why does it matter? That's it. What does that mean when we discuss "VAB"?

This best of the web article walks you through the three questions mentioned above, several advantages of vacuum aluminum brazing, and heating control.

An excerpt:

"The dwell time (soak) at braze temperature must be minimized as melted filler metal is vaporizing in the low pressure (high vacuum) environment. Too much filler metal vaporization can result in poor joint wetting and subsequent loss of joint strength and sealing ability. After the final brazing soak is complete, a vacuum cooling cycle follows, which stops material vaporization and solidifies the filler metal."

Read more: "The Beginner's Guide to Vacuum Aluminum Brazing (VAB)"